Manufacturing 300 Toy Airplanes

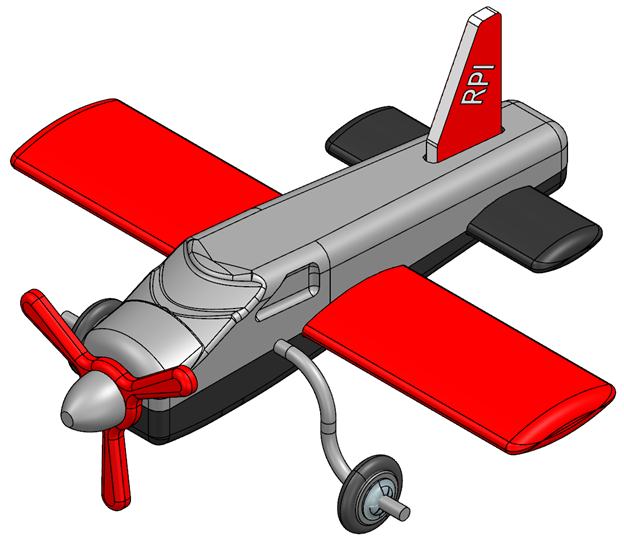

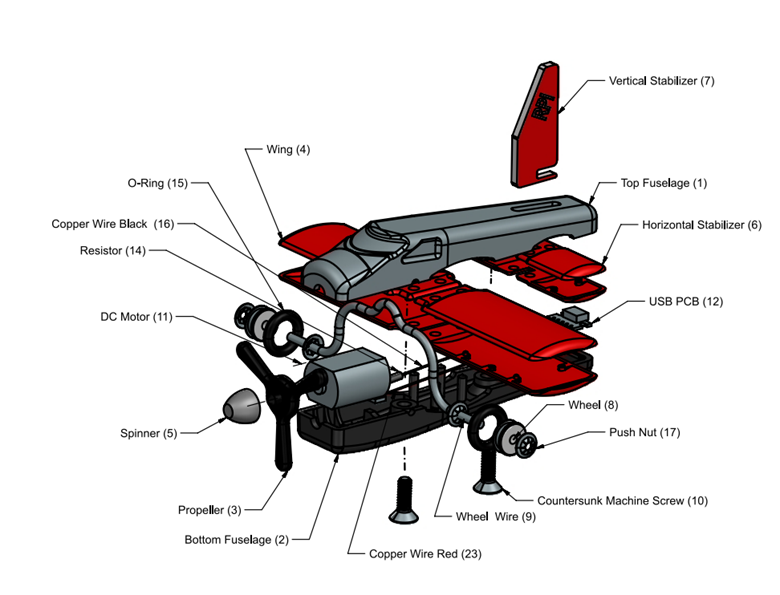

This project was part of the Manufacturing Processes and Systems (MPS) Lab I and II courses at RPI. Our task was to design, manufacture, and assemble 300 toy airplanes as part of a 12-person team. A CAD model of the completed airplane is shown below along with a diagram labeling all the components of the airplane.

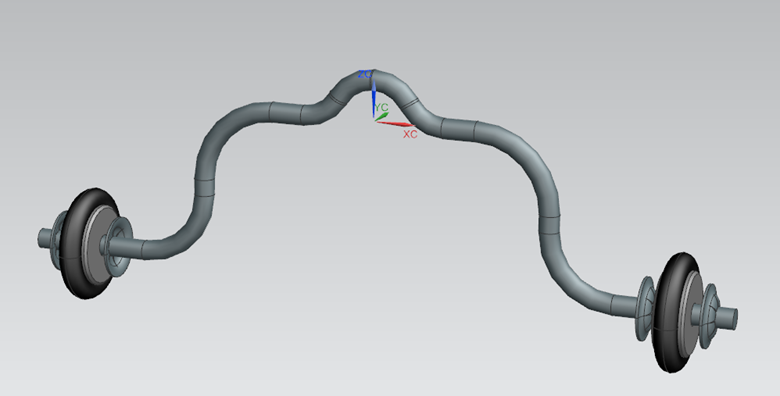

My first task was to develop a method to manufacture 300 wheel wires. Select the picture below to read about this subproject.

After the wheel wires were manufactured, I was tasked with developing a method to assemble sets of wheels onto each of the 300 wheel wires. Select the picture below to read about this subproject.

After completing the wheel wire assembly process, I volunteered to help with the robotic assembly of the wing and horizontal stabilizer halves. Select the picture below to read about this sub-project.

Through this project, I learned design for manufacturing (DFM) techniques and gained experience using various industrial machines such as Injection Molders, CNC machines, and pick-and-place robots. I also developed engineering, management, and interpersonal skills that are needed to design and manufacture a product as part of a large & diverse team.

An example of a finished plane and a stack of packaged planes can be seen below.

To view our final presentation slides, follow this link:

Final PresentationFor a more detailed and structured explanation of our project, follow this link to our Technical Data Package (TDP):

MPS Spring 2022 Plane TDPContact Me

Email: michael.aksen@gmail.com

LinkedIn: https://www.linkedin.com/in/aksenm/