Computerizing an Industrial Bandsaw

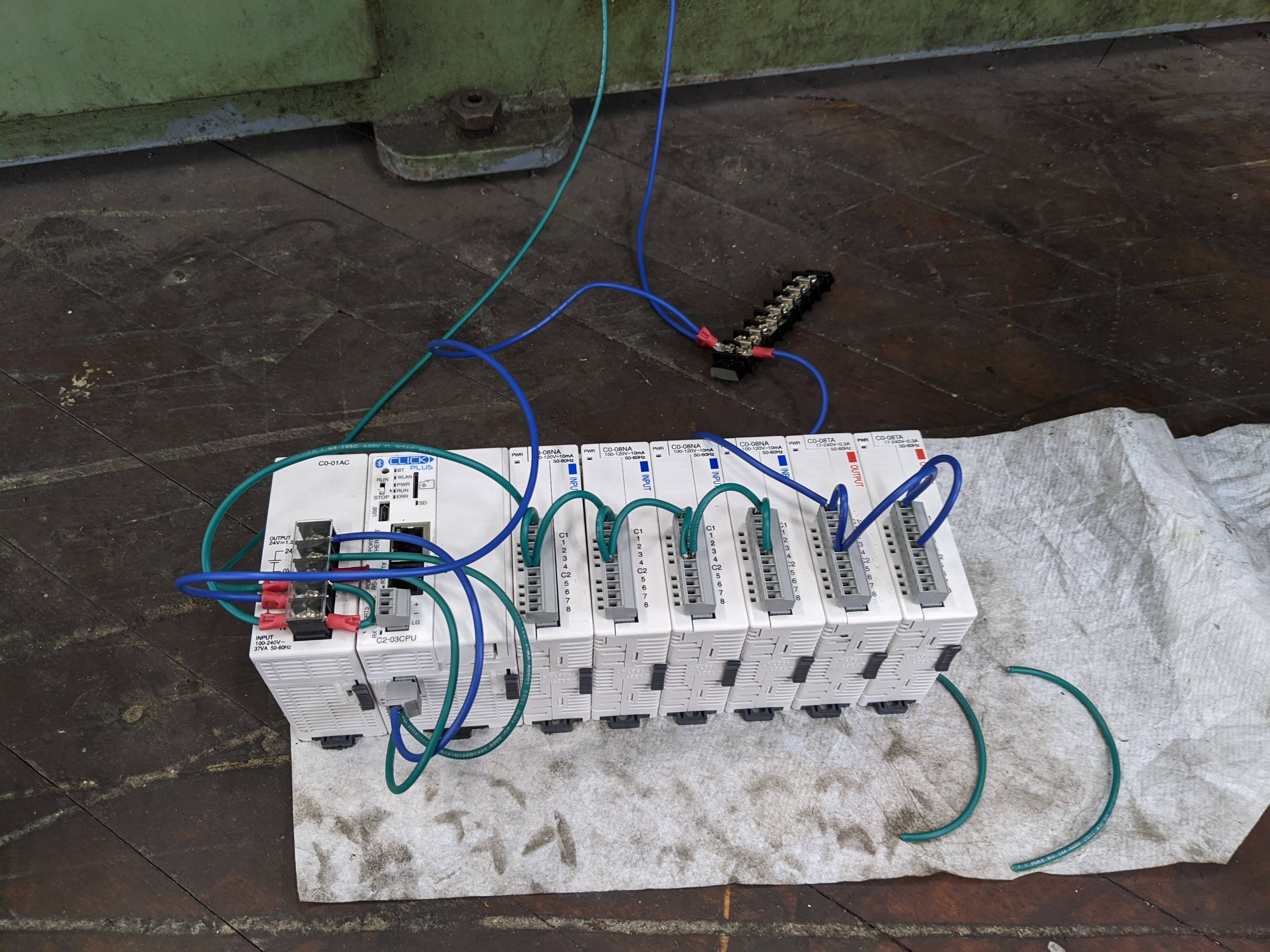

For this project, I was tasked with retrofitting a programmable logic controller (PLC) onto a 40-year-old Industrial Bandsaw and deploying Smart Manufacturing onto the machine. The bandsaw was owned and operated by a small manufacturing shop in Amsterdam, NY called The Factory Amsterdam (TFA). RPI’s Smart Manufacturing Innovation Center (SMIC) partnered with TFA to fund and provide support for my project.

After a few months, I successfully rewired the machine to the PLC and was able to control the machine’s operations via the PLC software. I was also able to connect the machine to a data analytics platform to collect data and improve the machine’s operations. As a result, what was an unreliable black-box only a few months prior became a key and dependable cog in the shop’s operations and a part of the industrial internet of things.

Introduction:

In the Summer of 2021, I was an intern at The Factory Amsterdam, an RPI Startup in the manufacturing industry. The shop they owned was located in an old factory building in Amsterdam, NY, with a beautiful view of the Mohawk river. One machine that I began working with was their semi-automated 40-year-old bandsaw, the C-1216A DoALL Production Horizontal bandsaw, which was used for cutting large quantities of stock. However, the machine suffered from frequent maintenance issues and misuse.

To address these issues, a project was proposed to retrofit a PLC to the machine. This would reduce downtime by establishing a systematic method for debugging issues using the PLC and it would improve the functionality of the bandsaw by expanding our understanding of the inner workings of the machine.

As the project progressed, its scope expanded to also include integrating a smart manufacturing architecture onto the machine to unlock its full operational potential. This project presents a case study that establishes key steps that any manufacturer can follow to modernize and connect their legacy equipment to the Industrial Internet of Things (IIOT).

The method comprises of three steps: 1) 'Planning & Investigation' to understand project constraints and assess feasibility, 2) 'Control Unit Integration' to rewire a machine from relay logic to a programmable logic controller (PLC) by a fully reversible process with minimal downtime, and 3) 'Bridging the IT/OT Gap' to establish network connectivity for data collection, and to develop a smart manufacturing architecture for operational optimizations.

Project Overview - Three Steps to Connect Legacy Equipment to the IIOT

Challenges & Solutions:

Electrical Documentation:

The first challenge I faced was that all of the documentation for the machine was illegible and not accurate. My solution was to dedicate several hours a week for an entire school year documenting the electrical connections throughout the machine, ensuring my understanding of the logic of the machine was thorough and reliable.

Localized Connections:

One challenge I faced during rewiring was how to connect electronic components that had no connection to the central control panel. The strategy I devised was to hijack local wires that were connected to the central terminal but were not needed by the PLC. These wires would be reconnected to the electronic component of interest and the signal would be passed to the PLC.

Bridging the IT/OT gap:

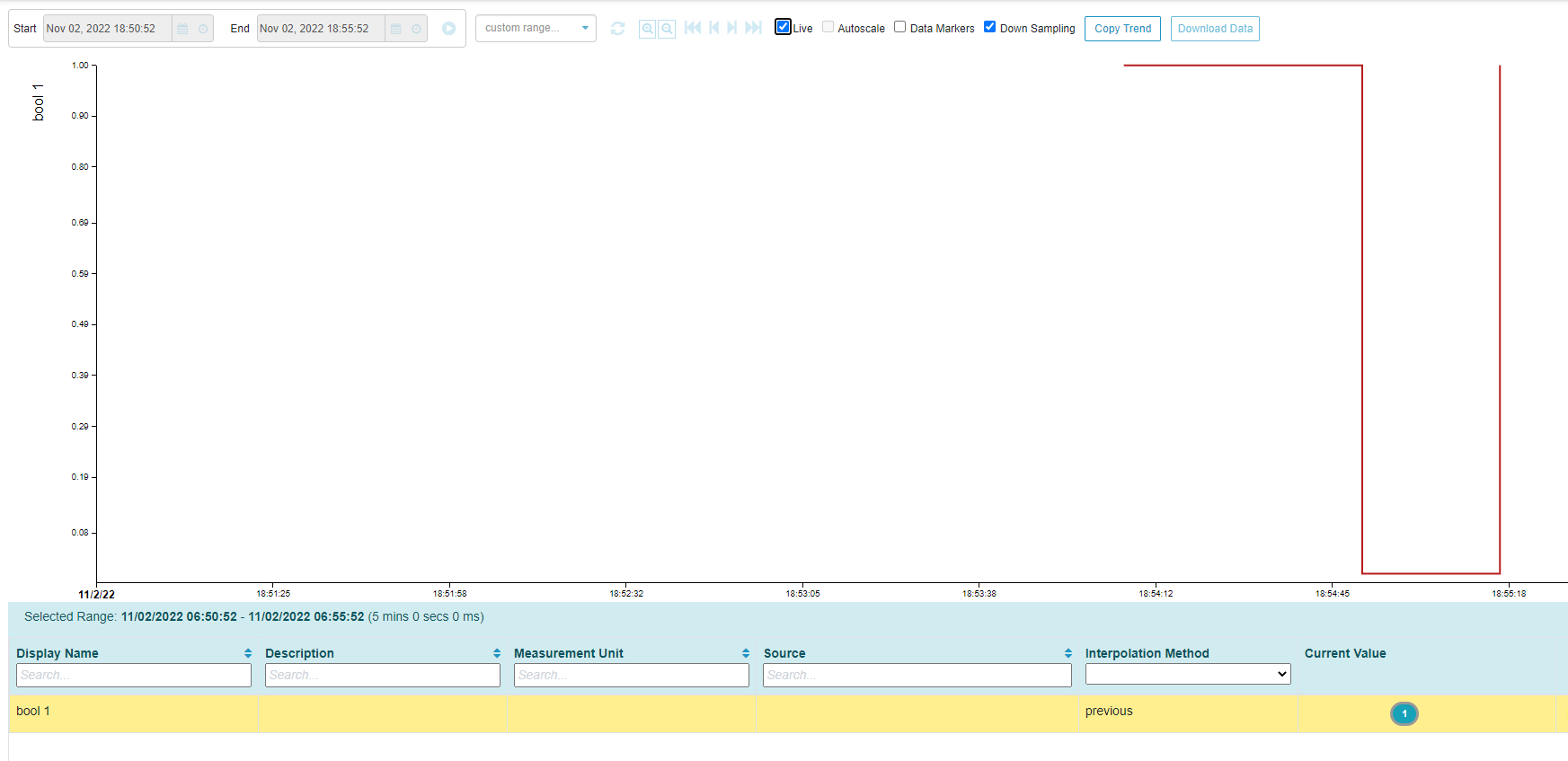

Another challenge was to actually receive data on the cloud-based data platform from the machine. This task required converting serial machine data to object-oriented variables.

The solution involved connecting the machine to a ModBus-OPC UA protocol gateway, which was then connected to a router via an ethernet cable, and a static IP was setup on a dedicated computer which sent the data through a secure local connection gateway to the data collection platform. Thus, allowing a data connection to be established for transmitting data to the SMIP.

This task was very difficult because there was no one I could speak to that could provide reliable advice on how to establish the connection, so only after months of experimenting was a connection finally established.

Collecting band speed data:

One interesting side project was collecting band speed measurements from the machine. The machine had a gauge that showed its band speed, but since it served no purpose in the logic of the machine its circuit was localized to the user control box.

After some investigation, I found that the gauge was an electronic gauge that was calibrated to a DC voltage value. A tachogenerator was used to convert the rotation of the band wheel that drove the saw of the machine to an AC voltage. This was connected to a rectifier circuit in the user control box to convert to a DC voltage that was then displayed as band speed in feet per minute (FPM) on the display gauge.

In order to collect this data, I purchased an analog input module that could read DC voltage at the appropriate range. I then rewired the rectifier circuit inside the PLC electrical box and connected the analog module to collect the DC signal. Afterwards, the signal was calibrated on the software side to display an accurate band speed.

Results:

The project yielded meaningful results for the bandsaw. The machine is now easier to maintain with a well-documented SOP and with PLC software that makes debugging issues a far smoother and more systematic process. With these improvements, the machine opens the window for more modern features like sensors and a human machine interface. Furthermore, the machine now has a greater capacity for operational optimization which affects characteristics such as cut quality and Overall Equipment Effectiveness (OEE).

Future Improvements:

- Energy Consumption Metrics: Attach a 3-phase current transducer to measure power output of the band and hydraulic motors for activity-based costing to estimate the cost of operating the machine.

- Preventative Maintenance using Acoustic Data: Test hypothesis that measuring acoustic data during cuts can predict the quality of the cut as well as the wear of the band to establish a predictive maintenance model.

- Automated Outfeed Table: Build an automated outfeed table to guide cut parts into a collection bin to convert the cutting process into a fully automated operation.

- Smart Manufacturing Dashboard: Machine dashboard to display smart manufacturing operational insights to the operator such as OEE, Power Consumption, and Machine Utilization.

Conclusion:

The modern manufacturing enterprise (MME) consists of cloud-connected computer-controlled machines for advanced controls and rapid integration of smart manufacturing insights. This renders capable legacy equipment obsolete for Small and Medium-sized Manufacturers (SMMs) transitioning to an MME to attain a competitive edge in their industry.

Establishing a smart manufacturing architecture on the legacy equipment enables the implementation of diverse operational improvements. This project proposes one method of converting antiquated industrial machines to the MME, allowing for a more centralized and efficient production environment. The project consisted of three parts: Planning and Investigation, Control Unit Integration, and Bridging the IT/OT Gap.

The short-term plan for the project involved integrating a control unit into the bandsaw, establishing an industrial network to a Smart Manufacturing platform, and developing a data model for contextualizing machine operations. However, in the long-term the vision was to transform the machine into a fully automated machine using an IIOT architecture, a Raspberry PI, and the PLC that would not require an operator for its cutting operations.

Future students and researchers at RPI can build upon this work by testing the data model on the SMIP, developing an operator dashboard for displaying real-time machine data, integrating power consumption data through a current transducer installation, and creating a predictive maintenance model for the machine's blade using acoustic data.

Personal Reflections:

At first the project seemed daunting, but every milestone and challenge was overcome through persistence and collaboration with my peers. The project demanded a lot of independent study and self-learning, so it was very helpful to have peers around me to consult with when I encountered difficult challenges.

This project has taught me how to learn independently, when and how to ask others for help, and it reaffirmed my own belief in my capabilities as an engineer. It also helped me understand my own interests and what I’d like to work on in the future. Furthermore, this project has given me invaluable experience working with PLCs and industrial machinery and has equipped me with the skills to tackle any engineering challenge I may encounter during my career.

Documentation:

I created a Standard Operating Procedure (SOP) for the bandsaw since the machine operators were not properly trained in the operation of the saw and as a result were occasionally misusing the machine. The SOP can be viewed here: Bandsaw SOP.

Demonstration of the bandsaw in operation:

Video of a sample cut: Bandsaw Sample Cut

Real Time Automation article discussing the project: RTA Article

Acknowledgments:

I’d like to thank Dr. Ghosh, Director of RPI’s Invent at Rensselaer Program, and Craig Dory, Director of the RPI Smart Manufacturing Innovation Center (SMIC), for acting as advisors for this project and as my mentors for two years. Also, I want to thank the Clean Energy Smart Manufacturing Innovation Institute (CESMII) for sponsoring my project. In addition, I want to thank The Factory Amsterdam (TFA), a local manufacturing shop started by RPI students, that trusted me (questionable decision) to work on their industrial saw to complete my project. I’d also like to thank Real Time Automation (RTA), an expert in industrial communication, that provided a protocol gateway for my project at no cost.

Contact Me

Email: michael.aksen@gmail.com

LinkedIn: https://www.linkedin.com/in/aksenm/